In order to promote our Kickstarter campaign, we’ve been doing a lot more press work. For the more technically oriented publications, that means explaining in detail the changes we’ve made to the car. When we get to talking about the rear ends, we inevitably get asked the same question. “Did you say Hadley Box? What’s a Hadley Box?”

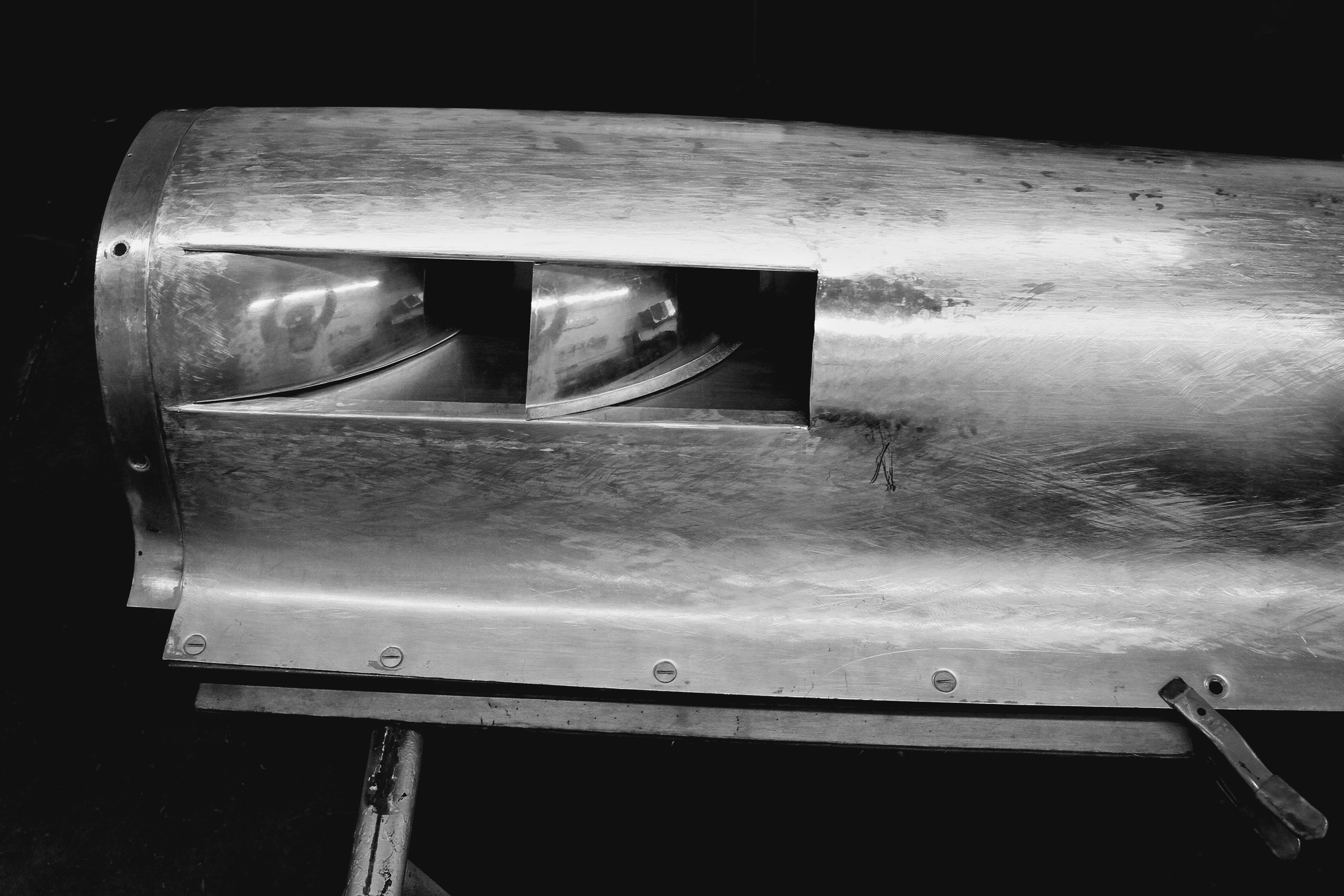

That’s a reasonable question. The Challenger II has two engines and is four wheel drive. That means it has duplicated drive trains that are mirror copies of each other. In order to achieve this, we actually had to mount the front engine backwards in the streamliner. The drive trains each have three components--a B&J three speed transmission, a Hadley Box, and a custom built rear end with quick change gears. The functions of the transmission and rear end are obvious. The Hadley Box is a little unusual.

Simply put, the Hadley Boxes mechanically connect the front and rear engines via a three piece drive shaft. The shafts coming off of the engines are mounted at equal but opposite 2.5 degree angles. The middle shaft is perfectly level. This connection allows the engines to remained synchronized during our runs.

Strictly speaking, this system is not mandatory. It’s certainly possible to connect both engines independently to the gas pedal. The Hadley Boxes are a safety feature that we’ve devised in order to keep the engines from running away from each other. For example, should the front engine fail during my run, under normal circumstances the rear engine would keep pushing, potentially resulting in a spin and a crash. With the Hadley boxes, the rear engine will mechanically know that the front engine is locked, the clutch will automatically drop it into neutral, and the rear engine will continue to power both sets of wheels independently to a safe stop.

That’s an extreme example, but the principle of communication holds true in less dire circumstances, including wheel slip, which will greatly impact our ability to make traction. As for the name, the Hadley Boxes are christened after Dave Hadley of SK Specialties, the only person crazy enough to build them.

Thanks for following along. See you next week.