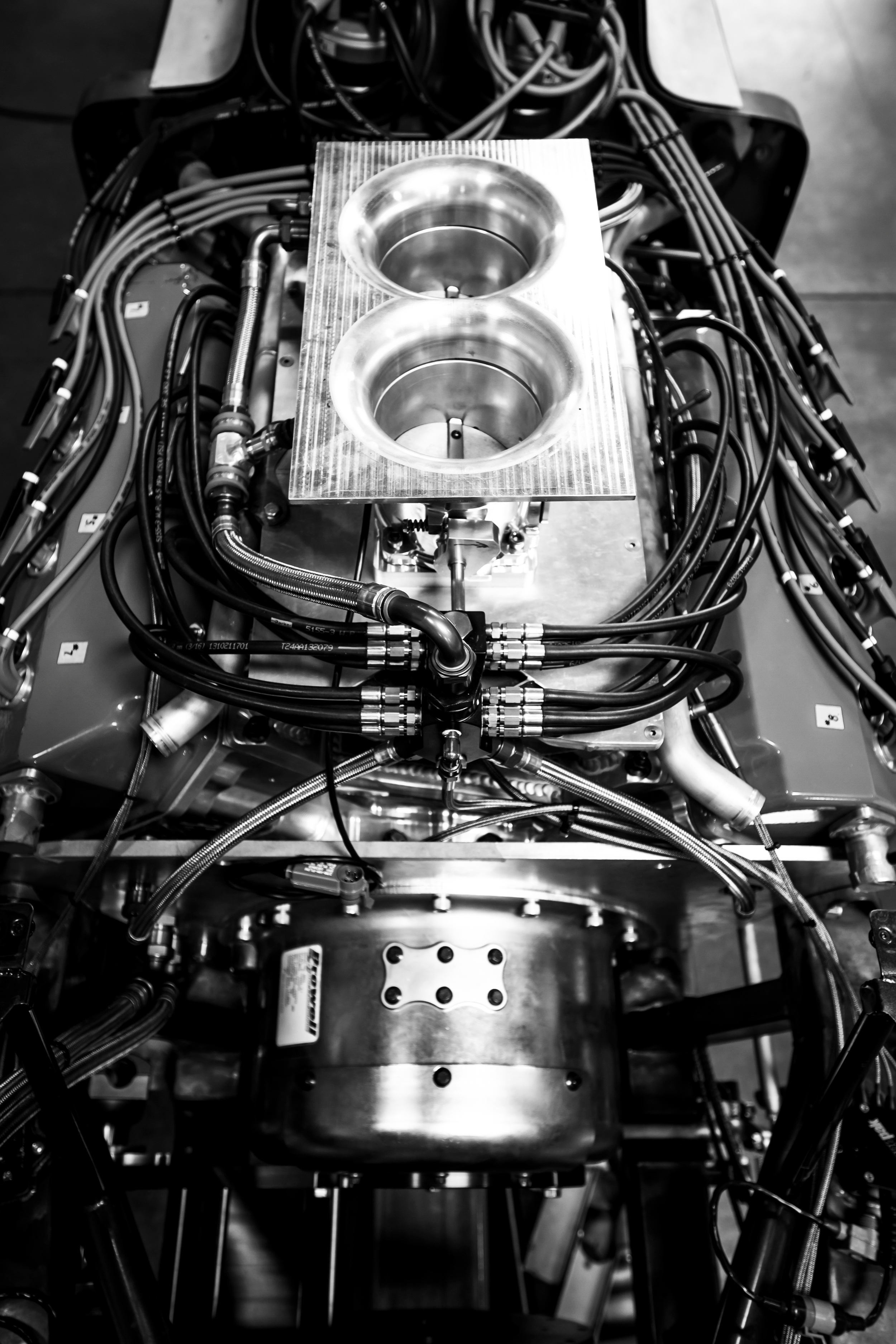

I'm delighted to announce that we have successfully started both of the Challenger II's engines. The initial run-throughs used methanol and sounded fantastic. After a few function tests, we switched over to 50% nitro, and the combined 4000hp roar shook the ground. It was a terrific feeling, and one that my team and I have been waiting a very long time for. Full credit belongs to our engine specialists Jerry Darien and Richard "RC" Catton. They made this happen, and I am extremely grateful for their dedication and hard work.

Looking ahead, we'll be doing a few more shop starts before our first shakedown run at a local drag strip. We've added a calendar section to the top of the website with more information about the dates and times of our testing events. Most will be open to the public if you'd like to attend. As per usual, the startup process has revealed some problems and inefficiencies, so we'll be working hard to correct and overcome those in the weeks ahead. Below you'll find a photo gallery and some videos of the startup. Every time I watch them, I feel overwhelmingly excited. I hope you feel the same.